Multichannel Ultrasonic flaw Detector AUGUR-TF

FEATURES OF THE AUGUR-TF SYSTEM

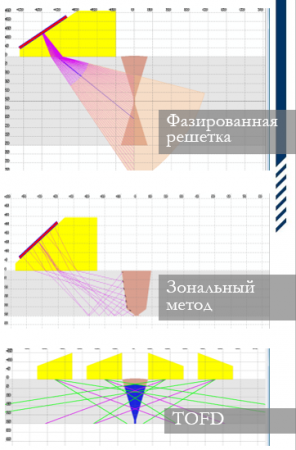

• Supports three modes of operation: phased array mode, zonal focus mode, TOFD mode, and digital antenna focus mode

• Identification and visualization of defects, determination of their sizes and coordinates

• Automated control of products and alloys up to 500 mm thick

• Combination with the AVIK module based on a laser profilometer

UNIQUE FEATURES

The combination of the best control methods in one flaw detector AVGUR-TF made it possible to offer an effective solution for automated ultrasonic testing of welded joints - the maximum return from ultrasound without loss of productivity:

• FR mode - effective search for defects of various orientations over the entire cross-section of the weld

• Zone focusing - control of the root and edges of the welded joint to detect lack of penetration, cracks, weights and other technological defects

• TOFD mode - additional information on diffraction echo signals from defects and bottom signals, defect height determination

• CFA mode - the most accurate visualization of defects, determination of the physical dimensions of defects

APPLICATION

Ultrasonic control of welded joints in FR mode

• Calibration of VLF / RFI and sensitivity by angle

• Calibration delay in the prism

• Calculation of the laws of focusing by depth, offset, beam path

• The laws of focus are calculated by the device itself without importing from a computer

• High performance data collection

• Combination of different methods using several groups in one pass, which increases control performance

• Creating a mask of the control object and obtaining an image after data collection make it easier to identify and dimension defects

• Compatible with scanners from various manufacturers

• Saving control data for later analysis

Ultrasonic inspection of welded joints in TOFD mode

• High sensitivity control

• Independence of defect detection on its orientation

• High control performance due to the control of the entire volume of the welded joint in one pass

• Saving control results for subsequent analysis

• Calibration Method

• Calculation of the control scheme using the specialized program "UZ calculator”

• Conclusions on the results can be adjusted and issued automatically

• Compatible with scanners from various manufacturers

Ultrasonic testing of welded joints in CFA mode

• Real-time digital focusing antenna (DFA) for tuning

• The ability to evaluate equivalent reflectivity

• Measurement of the length, height and coordinates of defects with high resolution

• Maximum ability to classify defects

• The use of various processing algorithms by CFA method for objects of control of increased complexity

• Obtaining high-quality images to increase the reliability of the quality of the object

TECHNOLOGY

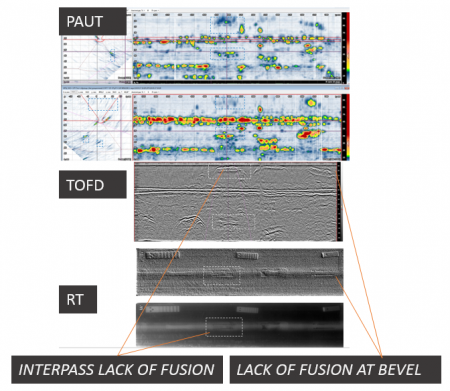

Automated ultrasonic testing in TOFD + HEADLIGHT mode

In the main mode, the control of welded joints is carried out by antenna arrays located on both sides of the welded joint and operating in the sector scanning mode with focusing along the fusion border of the weld metal of the welded joint and the base metal. For reliable detection and dimensioning of vertical planar defects, the TOFD control is used in conjunction with the PAR function.

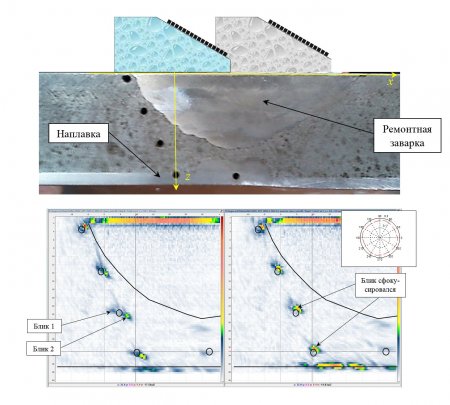

Anisotropy accounting

A 37 mm thick sample with repair welding and five side holes with a diameter of 2.2 mm. By taking into account the anisotropy in the tea leaves, the focusing of the glare has noticeably improved and the glare has become more closely correspond to the real position of the boundaries of the holes and the bottom of the sample.

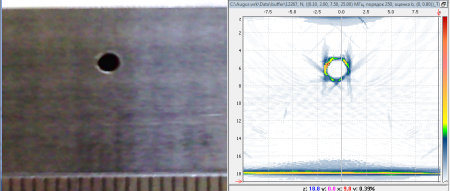

Multi-DSC mode

In the Multi-DSC mode, the obtained data are processed using the C-SAFT algorithm to obtain discontinuity images. Visualization of discontinuities is performed when the control data is presented in the form of a raster picture of the distribution of amplitudes in the established color palette. When visualizing discontinuities, the presence of reflections from the internal and external surfaces of the control object with a given shape, wave type transformations is taken into account, images obtained using several control schemes are combined in one image.

Software

The AUGUR software (software) installed on the control computer provides job control, collection, systematic long-term storage and processing of data using the C-SAFT algorithm, calculation of focusing laws, data visualization, and provides functions for data analysis and automation of the preparation of the control protocol. The flaw detector software package includes three main blocks of programs:

• “Data Logging”

•"Data analysis"

• "UZ calculator"

The “Data Registration” program is designed to configure control parameters, manage scanners, and record the initial control data in the general system database.

The program “Data Analysis” is intended for processing control data from a database, visualizing discontinuity images, analyzing control results and preparing a final conclusion on the results of control.

The UZ Calculator program is designed to calculate the laws of focusing antenna arrays taking into account the geometry of the welded joint, as well as to calculate the control parameters by the TOFD method.