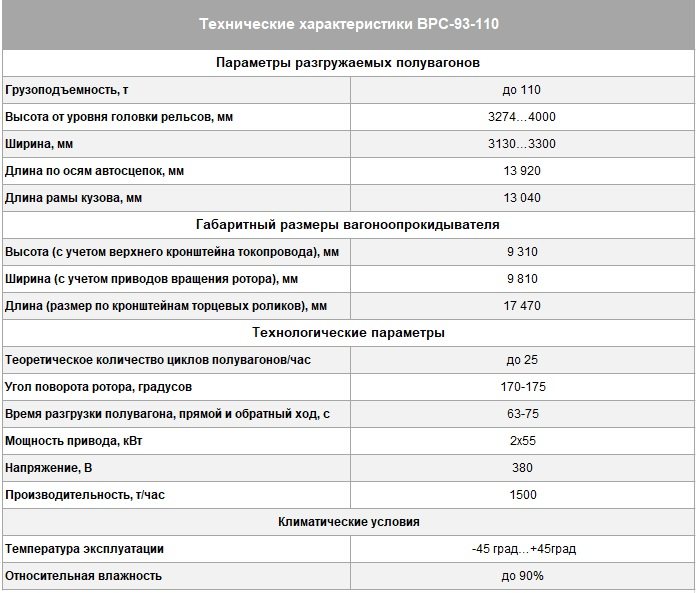

VRS-93-110 car tipper

Scope of car dumpers: thermal power plants, metallurgical plants, by-product coke production, mining and processing plants.

Rotary car dumpers of the ВРС-93-110 type have a rotor that rotates 175 ° relative to the longitudinal axis. Rotation of the rotor is provided by a special-purpose electric drive designed for cyclic alternating loads. The loaded wagon is fixed in the movable cradle by the rotor due to gravitational forces. Unloading from the gondola car is carried out into a buried receiving hopper. For cleaning the walls and bottom of the gondola car, the car dumper is equipped with overhead vibrators.

Principle of operation:

The car dumper works in conjunction with the car pusher. A loaded gondola car is installed by a car pusher on a platform inside the car dumper rotor and is fixed inside. Then the car dumper rotates around the longitudinal axis, as a result of which the cargo falls on the grate of the receiving hopper. At the moment of overturning, the car vibration cleaning system is additionally switched on, which contributes to better emptying of the car.

At the end of unloading, the empty gondola car is pushed out of the car dumper using a car pusher, after which the next car is fed.

The main advantages of the car dumper:

- the ability to unload most types of open wagons

- high productivity (up to 25 cars per hour) is ensured by equipping electric drives with frequency converters (FC), which

allow you to adjust the speeds of different stages of the unloading process

- minimizing human participation in technological processes due to a high level of process automation

- low power consumption in comparison with grab unloading

- high accuracy of all operations due to the use of sensors in the control system of the car dumper

- ease of maintenance is ensured by a well thought-out arrangement of mechanisms and the use of a centralized lubrication system for all units and connections

- long service life (estimated service life is 25 years) is provided by well-developed design solutions that

obtained as a result of a large number of strength and kinematic calculations of the car dumper

- a wide temperature range from -45 ° C to + 45 ° C is ensured through the use of special steels and accessories

- each car dumper in the basic version is equipped with a remote monitoring system that allows you to control the parameters and operation

systems and mechanisms in real time and issuing diagnostic messages in case of deviations

- special electrical equipment is used to work in hazardous areas

- as an option, it can be equipped with an electronic weighing system